At ATS, qualification testing for the nuclear industry is our specialty. We have been performing Environmental Qualification tests since 1986. Our nuclear testing services include harsh environment qualification tests for the Nuclear industry (e.g. LOCA testing and HELB testing) as well as accelerated aging of components and materials.

Note that the US NRC considers many of the activities associated with qualification testing, including determination of test requirements and evaluation of test results, to be “engineering” and has issued nonconformance notices to organizations that fail to properly account for this fact. Unlike some other labs offering nuclear qualification testing, ATS is a licensed engineering firm and every one of our nuclear test programs is directed and supervised by a responsible licensed Professional Engineer. Protect your investment by trusting your test program to an experienced lab that is licensed to legally provide engineering services.

Setting up Large Chamber Test

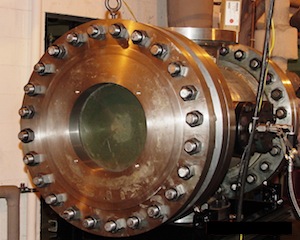

Five-foot LOCA Chamber

20-inch LOCA Chamber

ATS’ five-foot diameter LOCA testing chamber will accommodate most large specimens (e.g. valve actuators). Our 20-inch chamber is also available for smaller equipment resulting in both cost control and improved availability.

ATS’ in-house machine and fabrication facilities support and supplement our testing capabilities. Fixtures and other custom equipment required for your test can be designed and fabricated by ATS, saving you time and money.

Our boiler, superheater, and accumulator facilities provide the necessary energy to meet the most demanding test curves. This includes the over 800 °F per second (~450 K/sec) ramp rate required for the Westinghouse AP1000® Zone 1 test.

Read more about our facilities.

For companies seeking to enter the nuclear equipment supply industry, we are proud to offer engineering (feasibility) testing services through our Nuclear Gateway program.